Mining, Civil and Construction

Ardello Engineering has been providing manufacturing, remanufacturing, repair & maintenance, collaborative product development, welding & fabrication services to the mining, civil and construction industries for equipment used across all phases of a project for over 23 years. Our capacity and capability enables geometrically complex components and assemblies to be produced and economically repaired to our customers specifications and standards.

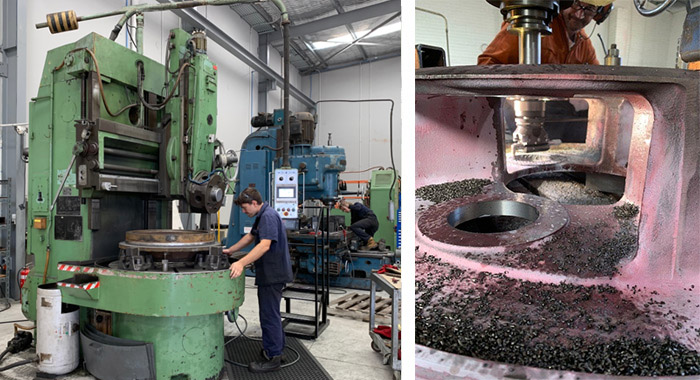

Our team comprises dedicated and experienced staff and first-class machinists who operate a range of lathes, horizontal borers, vertical borers, slotters, drilling, milling, rotary, cylindrical and surface grinding machines. Our welding capability extends to rebuilding worn and damaged surfaces by using conventional stick welding, MIG & TIG systems as well as by the more specialized technologies associated with metal arc spraying.

Equipment

Examples include but are not limited to; Transmission and Drivetrain Housings. Final Drives & Sprockets, Planetary Carriers, Yolks, Sensor Port Reconstruction, Intermediate Plates, Adaptor Plates, Spacers, Pistons, Shims, Spindles, Hubs and Housings.

Metal Arc Spraying

- Dimensional Restoration

- Sacrificial Corrosion Coatings

- Custom Alloy Coatings

- Bearing and Seal Surface Reclamation

Pump Components

- Shafts, Impellors, Rings, Cones

- Volute Repairs

- Bearing and Seal Surface Reclamation

- Dynamic Balancing

- Welding

Welding & Fabrication

- TIG/MIG & Stick Welding processes are routinely utilised during manufacturing, repair and maintenance of equipment.

- We undertake repairs on Cast Iron, Aluminium and Carbon Steel Housings and Casings

A commitment to honesty, integrity and a can-do attitude enables specialised services to be undertaken confidentially where products are manufactured and remanufactured to customer specifications.